The metal industry has numerous effects on the environment, including direct and indirect energy consumption of various sources such as water, electricity, gases, and the production of effluents. As a responsible manufacturer, Swiss Profile is aware of the importance of taking action to minimise the environmental impact of its activities, wherever economically and technically possible. For this reason, over the past decade, the company has undertaken many key projects and investments that reduce its carbon footprint.

A sustainable and economical approach to the production of gas for heat treatment

Heat treatment is a key step in the production process. It requires the use of gases such as nitrogen and hydrogen, mainly for annealing or hardening stainless steel. With traditional methods of gas supply, such as liquid or bottled nitrogen, users have to bear hidden costs such as rental fees, filling and delivery surcharges, order processing fees and environmental costs. In order to reduce these costs, Swiss Profile has implemented an agile and eco-friendly solution whereby it produces nitrogen, the main component of air, from the compressed air available on the production sites.

With this sustainable and energy efficient approach, the company produces its own nitrogen directly on site using two generators to provide pure, clean and dry nitrogen gas. With this method, Swiss Profile has been able to eliminate regular deliveries by large trucks, reducing the impact on road traffic and thereby significantly reducing its carbon footprint.

By taking this measure, the company can rely on a constant supply, without ever having to worry about delivery delays. The risks of service interruption are therefore greatly reduced, which contributes to total customer satisfaction in the long term. By implementing this production process, the company also gains the ability to monitor its own purity levels. The generators produce pure nitrogen from 99.5% to 99.999%, or anywhere in between.

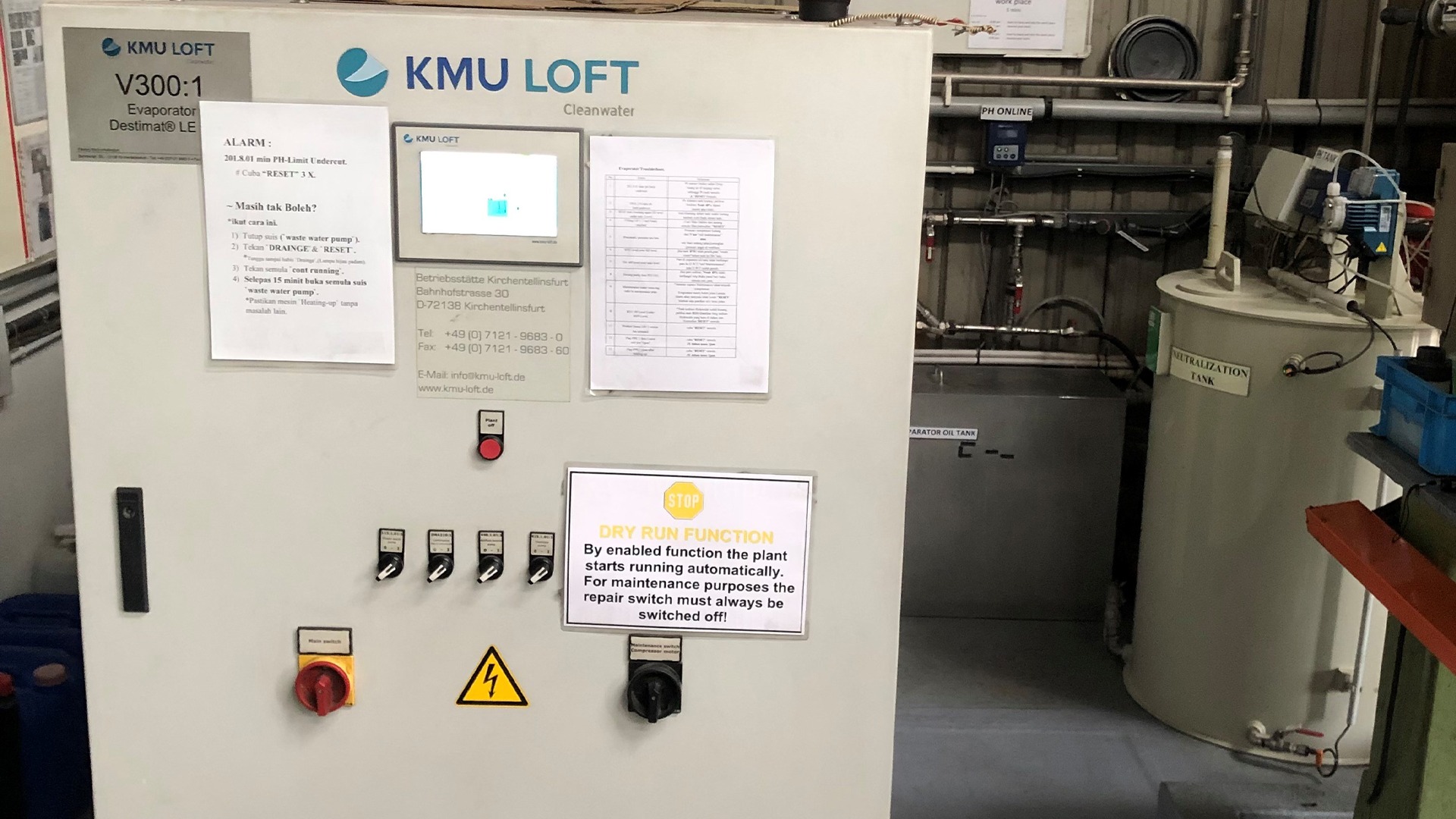

A system to recycle wastewater from chemical treatment

Water is an especially precious resource. It is essential to Swiss Profile’s production processes, especially during acid pickling or tumbling and degreasing with detergent, which generates different types of wastewater. The volume of water in this wastewater is 100 to 150 times greater than the volume of the chemical solution due to the constant supply of fresh water for washing and rinsing at the final stage of the chemical treatment process.

To protect this resource, the company has implemented a wastewater and industrial effluent treatment solution based on vacuum evaporator technology. The technique transforms the effluent into two streams, one of concentrated waste and the other of high quality water. The evaporator operates under vacuum, so the boiling temperature of the liquid effluent is lower, saving energy and increasing efficiency. The system recycles treated wastewater for reuse in production. The recycling process creates a valuable by-product that recovers and utilises up to 90% of the volume treated. Again, the implementation of this measure eliminates the need for road trucks collecting tons of wastewater. By using this vacuum evaporator, Swiss Profile reduces the volume of effluent that needs disposing of by 75%.

Effective initiatives to minimise environmental impact

Swiss Profile, as a responsible manufacturer, is very focused on its ability to minimise the environmental impact of its facilities. Calling practices green or sustainable has become all too common. This could even be seen as standard. On the other hand, taking actual steps to reduce consumption and the carbon footprint is our way of putting our money where our mouth is and working towards reducing our dependence on suppliers and contractors. Nitrogen production and wastewater treatment directly on site means increased efficiency in an economically viable approach. These initiatives clearly demonstrate the company’s commitment to environmental responsibility and profitability.