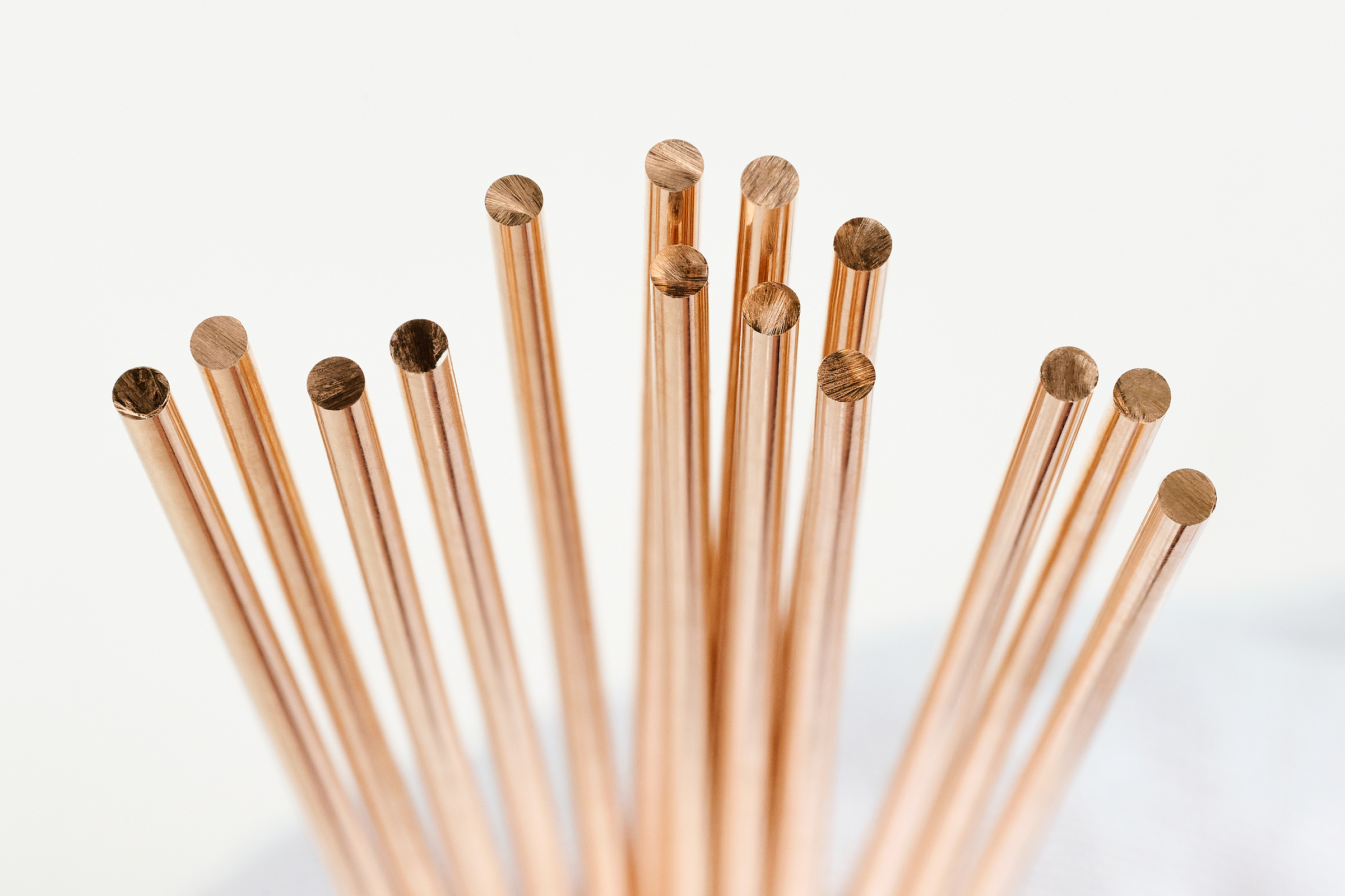

Within the fine wire department, PX Group has developed since the beginning of the year a new range of round wires made from innovative alloys, delivered to the United States. The first three alloys, based on gold, copper, and nickel, were developed in close collaboration with our client. Two new compositions, this time incorporating silver, copper, and palladium, have enriched this range in recent weeks.

These five alloys are part of a new family of industrial brazing solders. Brazing is a joining technique that does not involve melting the base materials, allowing for precise and aesthetic joints such as those used to attach horns to the middle of high-end watch cases. In industry, this method is particularly useful when the materials to be joined are too dissimilar to be welded, such as metal and ceramic.

Vacuum brazing imposes strict requirements, notably those defined by the American Welding Society. The content of volatile elements, such as zinc, must be below 0.001%, or 0.01 grams per kilogram. The alloy must also melt without spatter. These criteria required the implementation of specific control methods, developed in synergy with our teams from Foundry the laboratory of sworn assayers, R&D, and quality.

Beyond the technical aspects, transatlantic logistics posed a challenge that was brilliantly met by our colleagues from shipping and the dock.

"*" indicates required fields