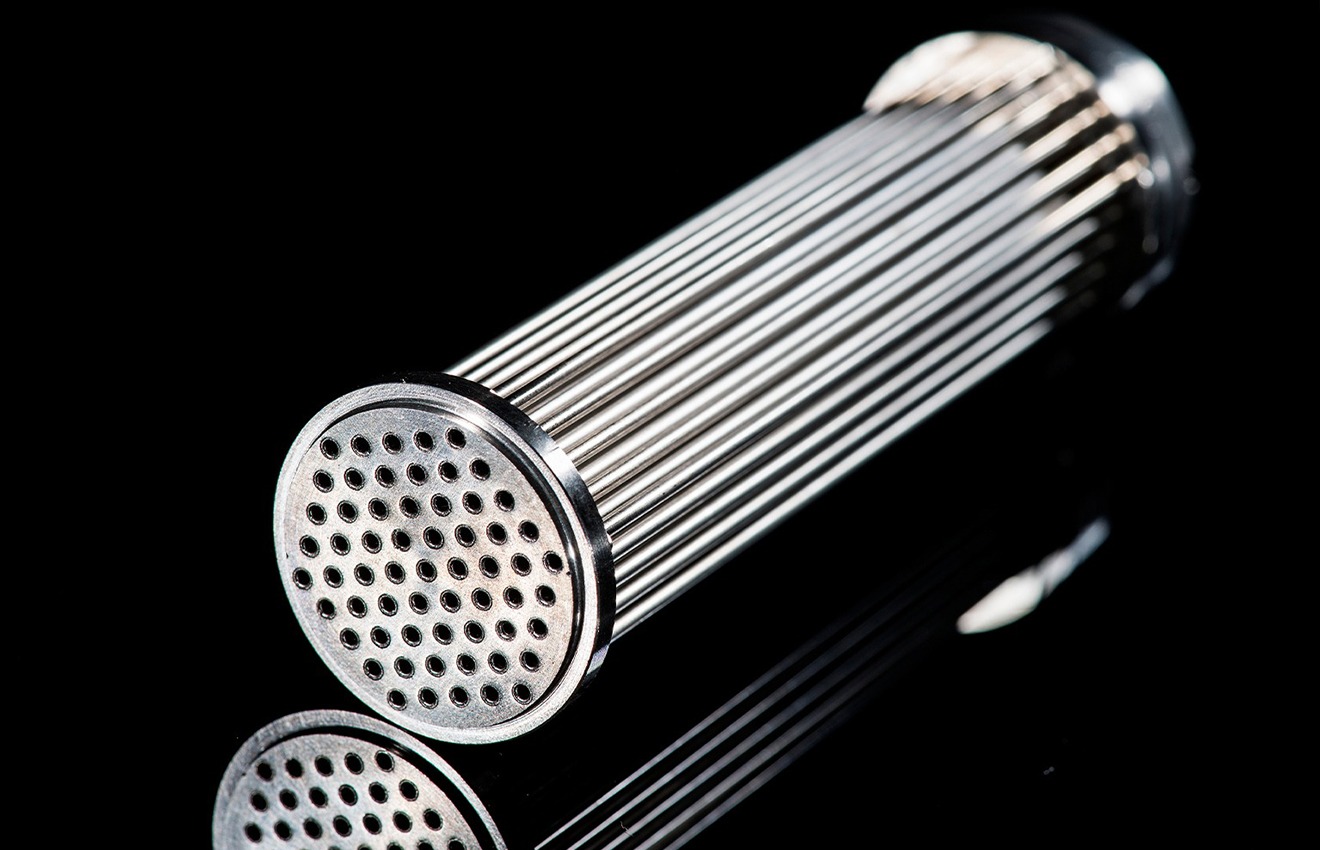

All precious metal alloys are developed and produced in-house by PX Précinox. Semi-finished precious metal products come in a variety of forms, including complex profiles and tubes, fine wires, machined parts, marker rings and banking products.

These high-end precious metal components are used in the luxury goods, medical and high-tech industries.