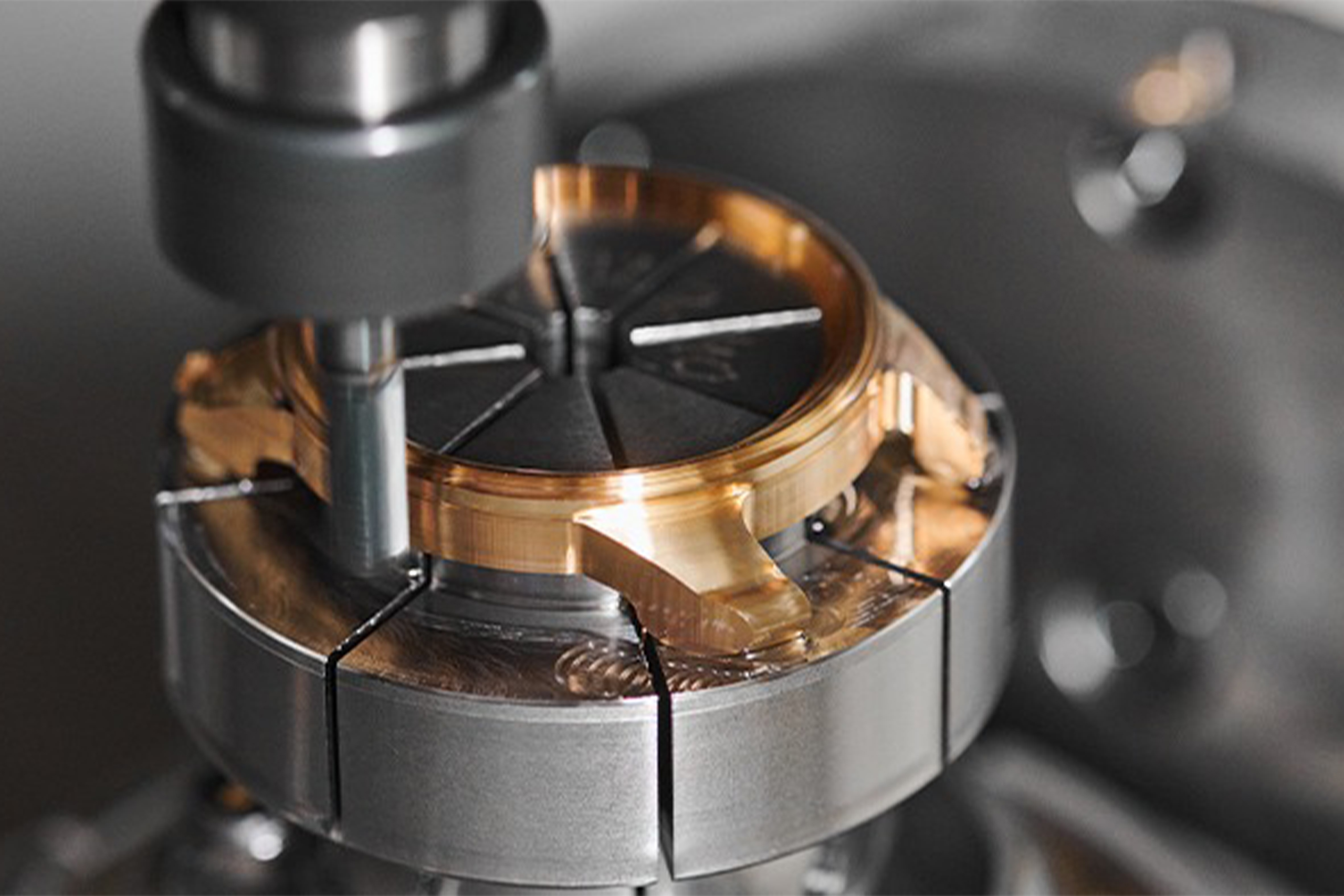

PX Précinox offers machining services for components from alloying to roughing, as close as possible to the finished part.

Machining is carried out after modeling 3D blanks, and can reduce precious metal feed rates by up to 75%, which means less material storage time and less waste to process.