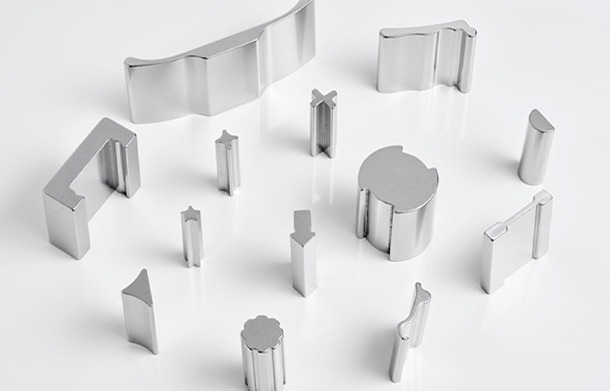

Semi-finished products made of non-precious metals, such as profiles, tubes or wires, are manufactured by PX Précimet (Switzerland) and Swiss Profile (Malaysia), according to customer needs. The technique of deforming non-precious metals is a proven know-how within the Group. These operations come from rolling, stretching and cutting.

These non-precious metal products are intended for the watchmaking, industrial, aeronautical and medical sectors.