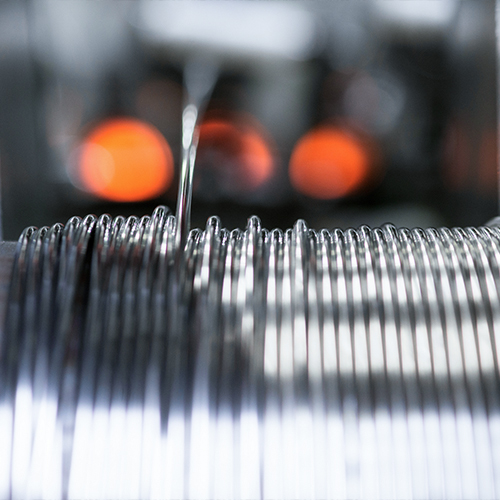

Wire drawing, or the reduction of wire bar diameter, is an operation that provides excellent dimensional stability and precision. Swiss Profile is equipped with wire drawing machines for the production of precision wires, and cylindrical grinding machines for the production of ground bars. PX Précimet is also equipped with wire drawing machines for the production of precision wires.

Non-precious metals

Round bars and wires

Round bars and wires

Applications

- Watchmaking / leather goods

- Medical

- Aeronautics

- Motion Technologies

- Industry (bar turning and various applications)

Alloys

- Titanium: Grade 2 – 3 – 4 – 5 – 5 ELI – 23 – 6AI7Nb

- Austenitic stainless steels: AISI 304, 304 L, 316 L, 316 LvM, 904 L

- Special steels: EN 1.4435, EN 1.4441, EN 1.4427So, Phynox (EN 2.4711), Nivaflex (2.4782), 17 – 4 PH, 15 – 5 PH, PH 13 – 8 Mo, A – 86, AISI 347

- Nickel alloys: Inconel 625, Inconel 718, Nimonic 80A

- Hardenable alloys for linear guides: AISI 420, EN 100Cr6

Dimensions

- 0.40mm to 12.00mm

- Any rod length from 1000mm to 6000mm

Other dimensions ⇒ on request

Tolerances

- Ø H7 for wires and rods without cylindrical grinding

- Ø H6 for centerless ground rods

- Straightness: <1mm/m

Other tolerances depending on the field of application.⇒ on request

Quality control

- Dimensional and hardness checks before delivery

Other features ⇒ on request

Finish

- Hardness on request: bright annealed, light drawn, half-hard drawn and full hard drawn

- Surface: cold-drawn, ground, sandblasted, satin-finished

Other ⇒ on request

Delivery

- In bars

- In reels

- In coil