Discover the RV75 coating, specially designed to withstand the highest thermal stresses. Its increased toughness and exceptional wear resistance make it the ideal choice for machining stainless steels, Stellite alloys and even Cobalt-Chrome. Thanks to its unparalleled performance, RV75 allows tools to retain their sharpness for longer, thus guaranteeing an optimal surface quality throughout your production.

The characteristics of RV75:

Exceptional tool life

Thanks to its hardness of 39 GPa, the RV75 coating significantly reduces wear on cutting edges. Cutting edges stay sharp longer, reducing the frequency of tool changes and ensuring optimal performance throughout your production.

Improved productivity

The RV75 coating retains its exceptional performance even at temperatures of up to 1110°C. This thermal resistance allows cutting speeds to be increased, which significantly reduces production time and improves productivity, without compromising the durability of the tools or the quality of the finish of the machined parts.

Optimize the safety of your production lines

Combined with its hardness of 39 GPa, RV75 has an ultra-low friction coefficient of 0.3 (compared to steel). This feature limits the risk of chips jamming in the flutes of the tools, drastically reducing the risk of breakage, particularly during drilling or grooving operations. This translates into greater reliability of your production, even in unmonitored machining or during night-time production.

The concrete impact of RV75 on your production:

- Optimization of costs: By extending the service life of tools and reducing downtime, RV75 results in a significant reduction in operating costs.

- Consistent performance: The coating’s robustness allows tools to retain their sharpness for longer, thus ensuring optimal surface quality over an extended production period.

Our customers who have adopted RV75 are already seeing a significant improvement in their results, both in terms of economics and the final quality of their products. Here are a few examples:

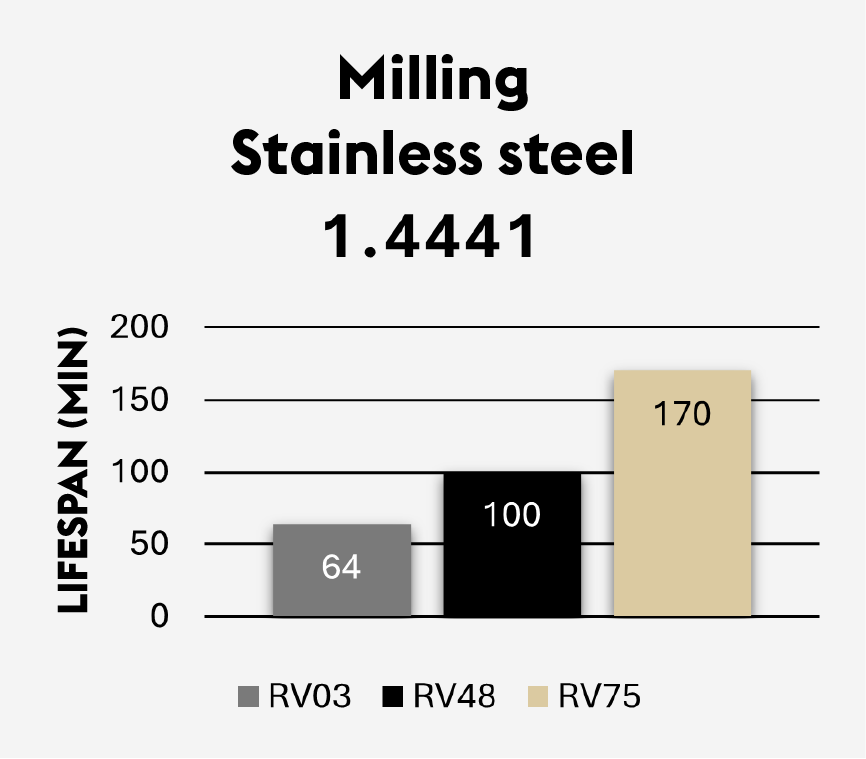

Contouring 1.4441 stainless steel

The RV75 coating offers a lifespan 70% longer than RV48 and almost 2.7 times longer than RV03 when milling 1.4441 stainless steel with a 0.80 mm diameter Z3 cutter.

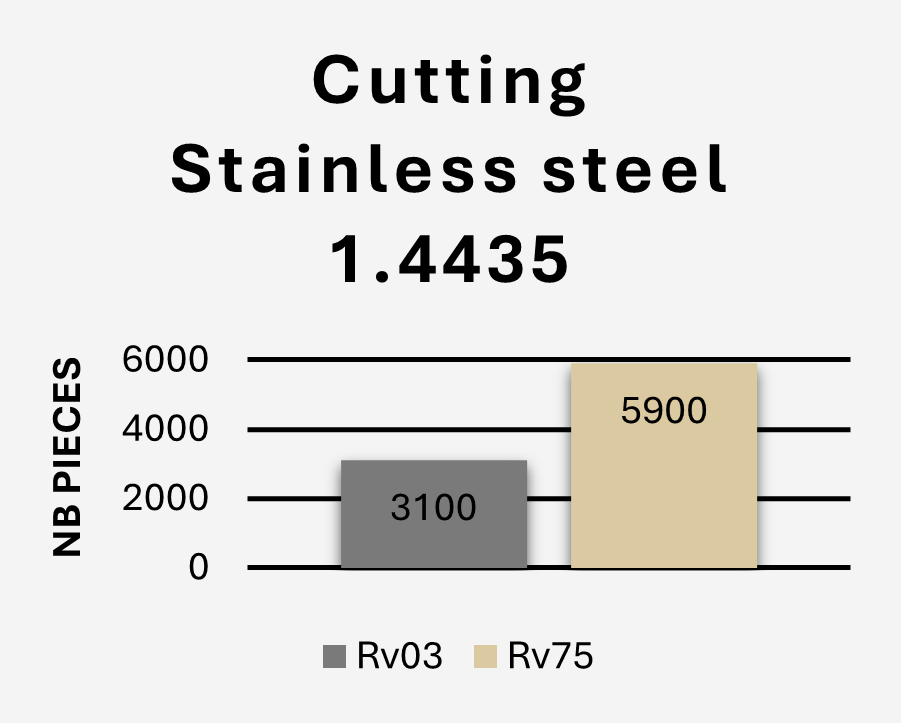

Cutting stainless steel 1.4435

The Ø50 mm, 0.90 mm thick, 80-tooth saw cutters with the RV75 can produce up to 5,900 parts, compared with 3,100 with the RV03. This represents an increase of almost 90% in service life, optimizing productivity and reducing tooling costs.