An Energy Saving Committee typically has the primary purpose of promoting and implementing initiatives that lead to reduced energy consumption within an organization. The goal is to contribute to lower energy costs, environmental sustainability, and often improve overall efficiency.

At Swiss Profile, our committee consists of individuals who were handpicked for their experience, knowhow, good work ethic to lead the improvement, promoting awareness and understanding of the importance of energy conservation to the mass.

Our first task was to formulate and recommend energy-saving policies, guidelines, and best practices for adoption by the organization. Simple efforts like switching off lights when not in use and setting the air-conditioning temperature at 25 degrees Celsius can be quite a task at the beginning.

But when the results showed significant energy cost reduction, it created a positive chain reaction where you see people been more conscious about energy consumption.

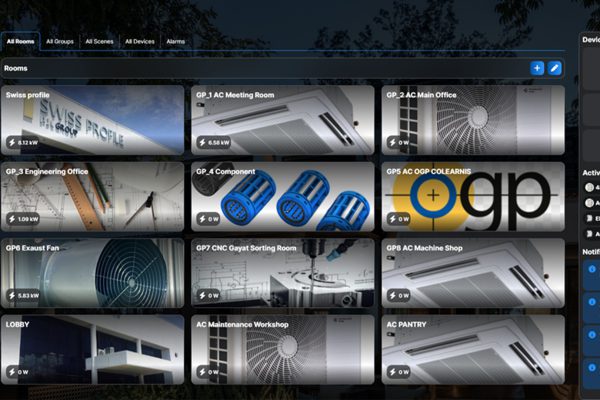

This is a result of constant tracking of energy consumption patterns, producing education videos through Colearnis, our co-learning platform, monitoring progress towards energy-saving goals, and preparing regular reports for analysis in our biweekly meeting.

We cannot say enough about providing training and educational programs to employees on energy-saving practices and encouraging behavior that contributes to energy efficiency.

We have in the pipeline to do an Energy Saving GEMBA where we conduct regular energy audits to identify areas where energy is being wasted and propose solutions to improve efficiency. We are looking into programs that reward individuals or departments for contributing to energy-saving efforts.

In our manufacturing environment where we use compressed air to operate, wastage is unavoidable like air leakages via hoses, couplings, and devices. There are a lot of hidden costs due to leaks in compressed air, gas, steam, and vacuum systems. Not only these are extremely expensive, but they are one of the largest sources of energy wastage in the production industry. A single 3.00mm leak can cost up to EUR 6,000 a year.

We can eliminate this by having devices such as Acoustic Imager where we can visualize leaks, partial discharge, and mechanical issues. Repairs can be deployed quickly to stop the wastages.

With collaboration with our counterpart in Switzerland, we explore into new technologies and methods for energy conservation. In time to come, we are interested in working with external organizations, government agencies, and industry partners to share knowledge, leverage resources, and promote energy conservation on a broader scale.

With such aspiration, the Energy Saving Committee plays a crucial role in fostering a culture of energy awareness and responsibility, contributing to sustainability goals, and ultimately reducing the environmental impact associated with energy consumption.

For your better tomorrow, save energy today!