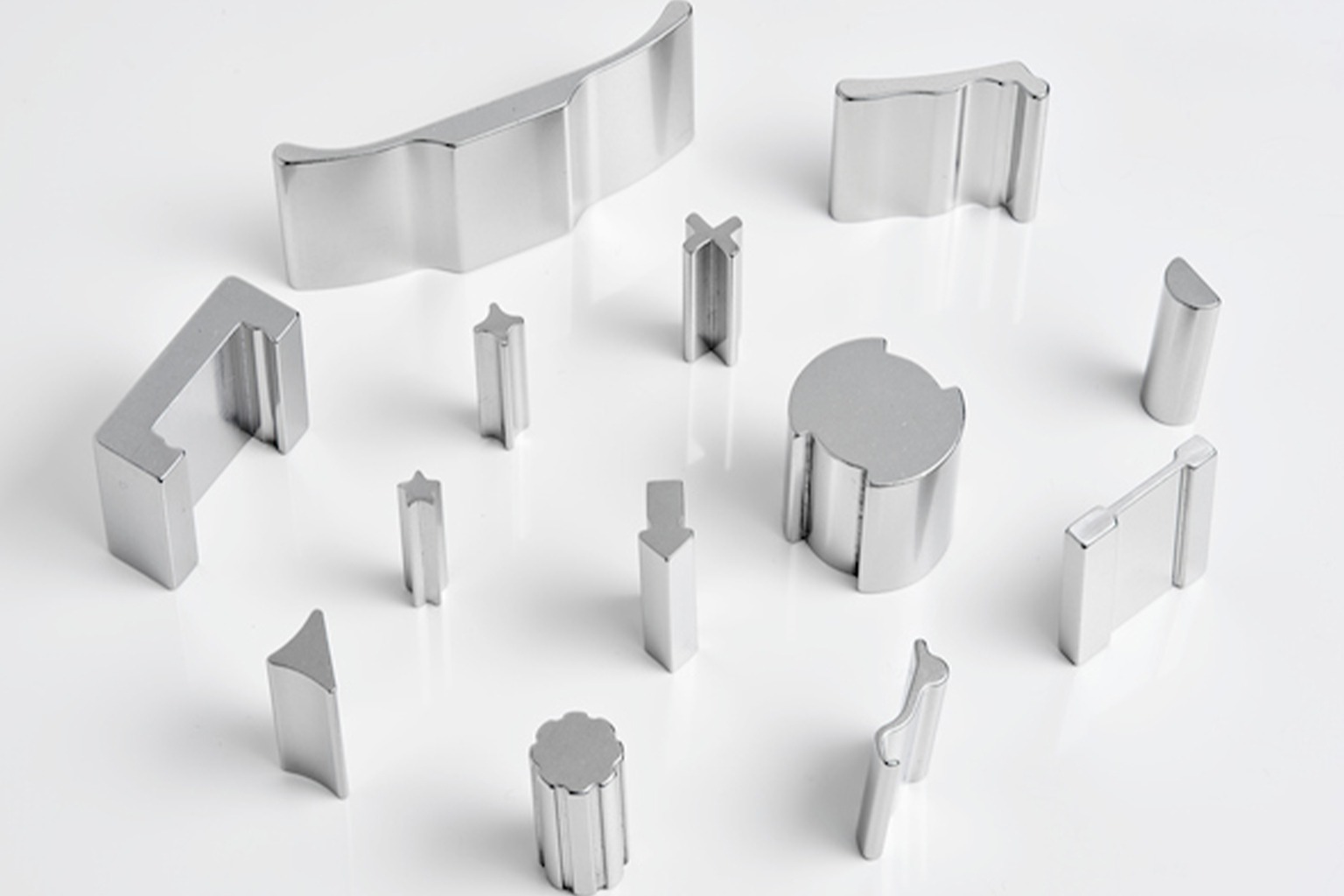

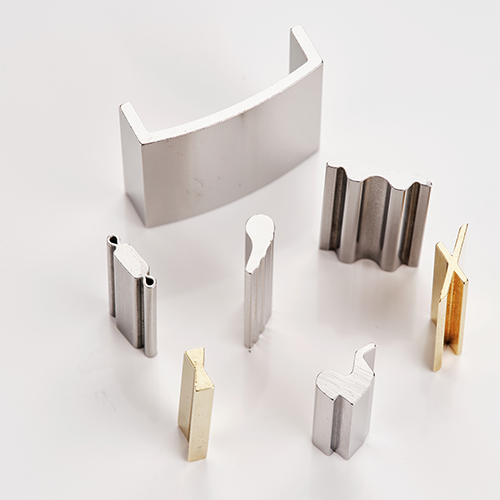

PX Précimet and Swiss Profile manufacture complex non-precious metal profiles and tubes in a wide range of metals, with exceptional quality and precision in terms of geometry and surface finish, perfectly mastered by the company’s technicians and experts.

The company has perfect command of rolling, strain-hardening, drawing, welding, milling and continuous machining. The various processes are judiciously combined with the appropriate heat treatments, to obtain the profile geometries and mechanical properties that our customers require.