The primary objective of any company remains customer satisfaction. Based on this premise, operational excellence places the customer at the heart of all value chains, from the sourcing of raw materials, to the delivery of the finished product, to the well-being and recognition of all stakeholders. This approach is an integral part of our corporate strategy. With this in mind, PX Group SA has begun to roll out the PhoeniX project, which will ultimately aim to optimize work processes.

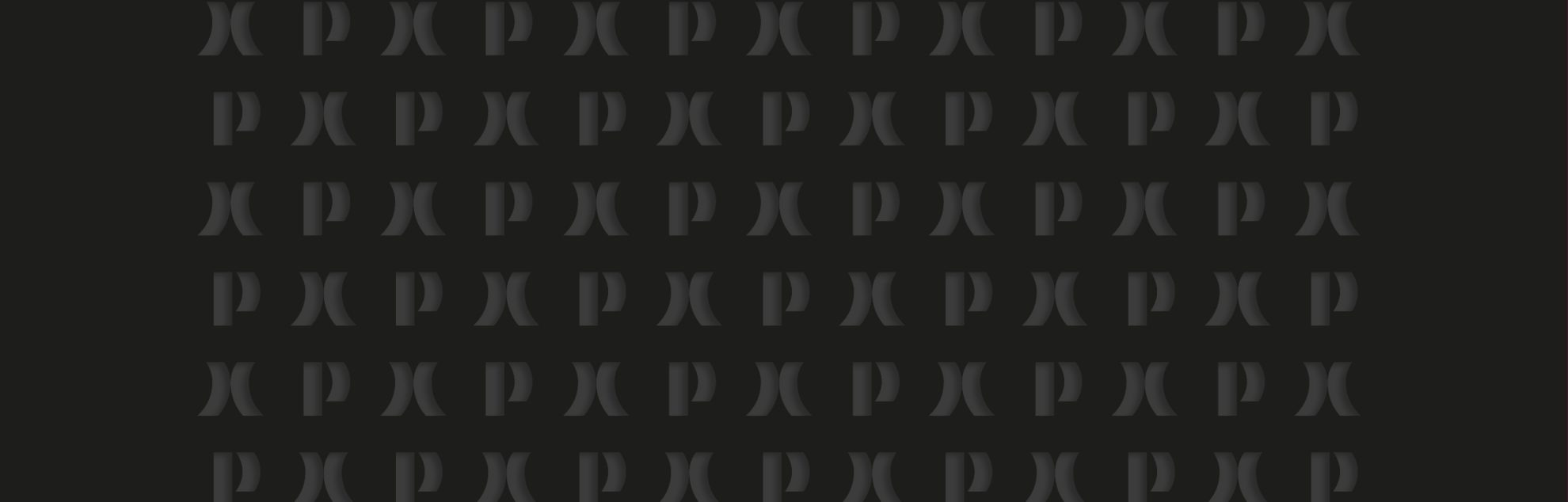

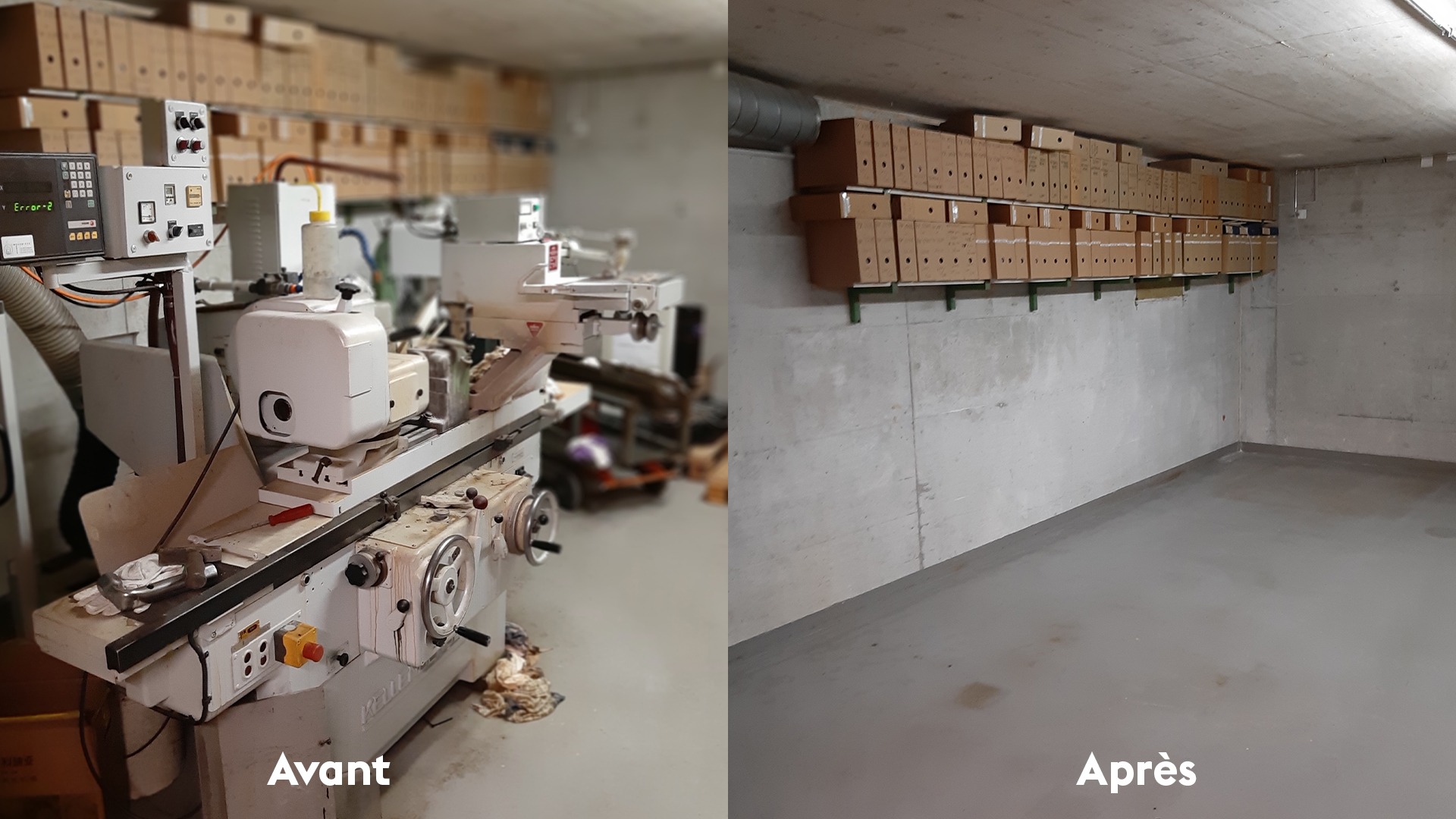

First phase of the project: an efficient work environment

The application of the 5S method is part of this first project phase, and 5S aims to optimize the conditions and environment of the workspace through participative management at all hierarchical levels.

In terms of challenges, it sets the course for a clutter-free working environment, asking the right questions, applying visual management wherever possible in the company, self-assessment, encouragement, simplification and rewarding success.

It is divided into 5 implementation stages:

- Remove the unnecessary, Eliminate (SEIRI)…sort according to frequency of need

- Put away (SEITON)… in a specific place for easy retrieval

- Clean (SEISO)… to detect anomalies and premature wear

- Organize & Standardize (SEIKETSU)… define the rules to make it obvious

- Respect (SHITSUKE) … rules to maintain rigor

Second phase of the project: aiming for the five ZERO concept by getting it right thefirst time

Getting it right thefirst time is the challenge of implementing the Five Zeros concept, with the ultimate aim of catalyzing continuous improvement methods. The method is based on a gradual progression through five stages:

- ZERO DEFAULTS: limit defects and returns, reduce scrap and rework operations, in short, do it right the 1st time – visualize problems & find causes

- ZERO DELAY: continuous optimization of processes to serve the customer with the shortest possible lead time, whatever the order.

- ZERO TROUBLES: accelerate preventive maintenance – reduce corrective costs

- ZERO PAPER: drastically reduce the amount of paper in circulation

- ZERO STOCK: keeping inventories as lean as possible

This second phase has been supplemented by the TEMPO project, which will eventually provide better control of production times/stops through automatic acquisition and analysis of past times, tooling times, maintenance times, etc.

With its operational excellence approach, PX Group SA is committed on a daily basis to optimizing its management and workflow processes for the benefit of all its partners and customers.